Cardboard box

Application fields and characteristics:

The EN-2.5-J vacuum tube lifting device uses the principle of vacuum to lift and move workpieces, especially suitable for frequently and quickly lifting and moving cartons, bagged packaging, barrels, plates, etc., with a handling weight of up to 300Kg. When lifting workpieces, there is no need for cranes, mechanical arms, hydraulic cylinders, or other power sources; the operator only needs to use the control handle to adjust the system's vacuum level to easily achieve lifting and handling of workpieces. The higher the system's vacuum level, the higher the workpiece is lifted; as the vacuum level decreases, the workpiece is gently lowered.

Application range:

Loading and unloading machine parts or electronic components

Extracting and loading boxes or products into boxes

Handling woven bags, snake skin bags, rubber blocks

Stacking shrink film packaging or bagged packaging

Functional design:

Can lift 35Kg items with one hand

Ergonomic operation, easy to handle heavy items

A complete power supply device (electricity, compressed air, vacuum) integrated with cables and suspension rails

Safety adjustment of sliding area with limit blocks

Selection of load detection valve, safe and reliable

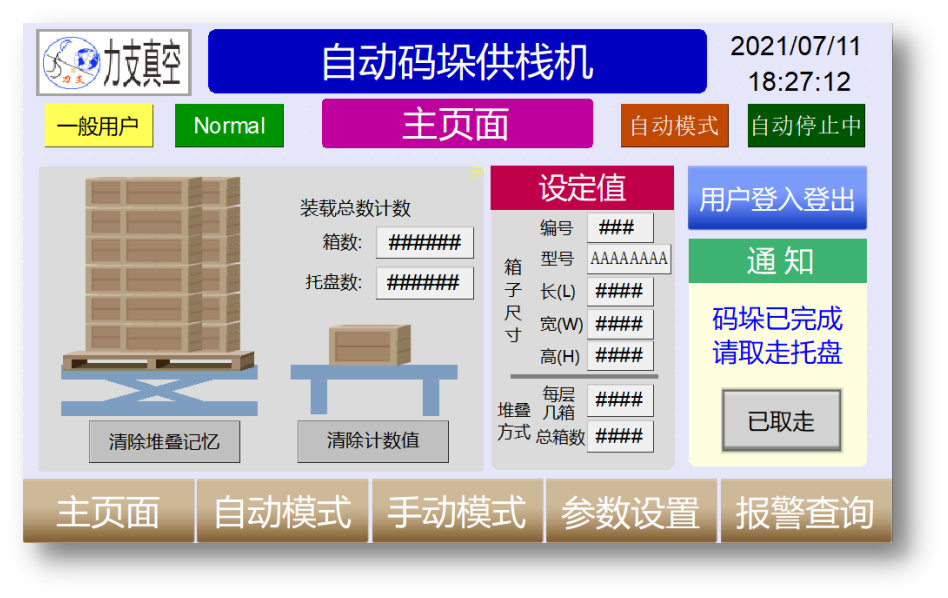

I. General provisions of the equipment

1.1Equipment name: Outboard engine stacking equipment

1.2Equipment function: Automatically stack packaged outboard engine boxes onto pallets

1.3Equipment capacity: Stacking speed approximately40S/Pcs

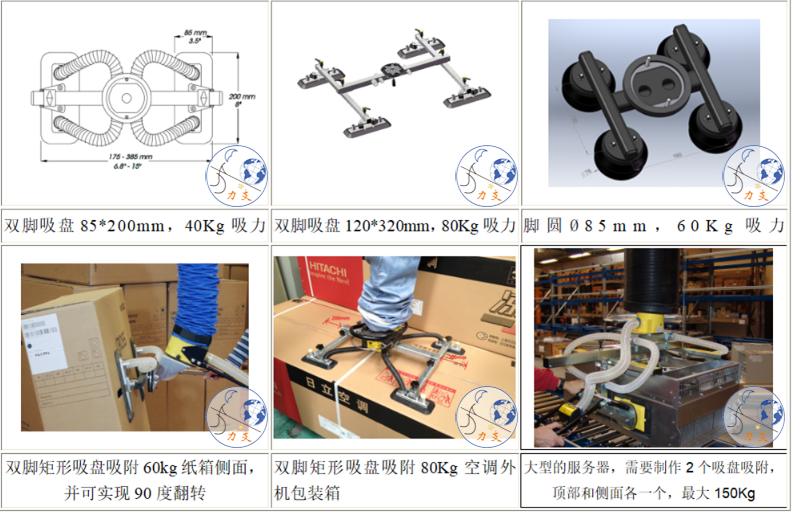

1.4Supporting equipment for the device:Automatic packing machine, vacuum suction cup,Hydraulic liftPallet disassembly and placement mechanism, etc.

1.5、Consumables: Electricity Compressed air

1.6Product conditions suitable for the equipment:

◆ Box body: Cardboard box, PEPlastic strapping

◆ Box body length:102~158(cm)

◆Box body width:47.5~76(cm)

◆Box body height:27.5~52(cm)

◆ Box body weight:MAX≤25to120㎏/box

II. Work process

◆ Box body suction: After the packing box enters and is positioned(the packing machine locates the packing box). The cylinder descends and sucks the packing box,after confirming the suction of the packing box, the cylinder rises.

◆YTo move: After the lifting cylinder confirms it has risen to the machine part,, Ythe transfer servo starts and moves the packing box to the designated position.

◆XTo move:YAfter the movement is completed,, Xthe transfer servo starts to send the packing box to the designated position above the frame..

◆ Box body release: XAfter the transfer enters the designated position, the lifting cylinder descends,to release the packing box onto the pallet..

◆ After the packing box is released,,the transfer mechanism returns to the original position,to perform the next cycle of work..

III.Design principles

◆ Applicability: Meets90%of automatic stacking of outboard power packaging boxes after packing.

◆ Advancement: The equipment possesses advancement, practicality, and reliability, with imported or well-known domestic manufacturers' products used for supporting equipment and components to ensure engineering quality,improving

production efficiency..

◆ Rationality: The overall layout design of the equipment fully considers the process flow of the production line, making the product process flow reasonable, and the equipment layout reasonable, tidy, and beautiful.Line生产的工艺流程,使用户产品工艺流向合理,设备布局合理、整齐、美观。

|

|

|

|

|

|

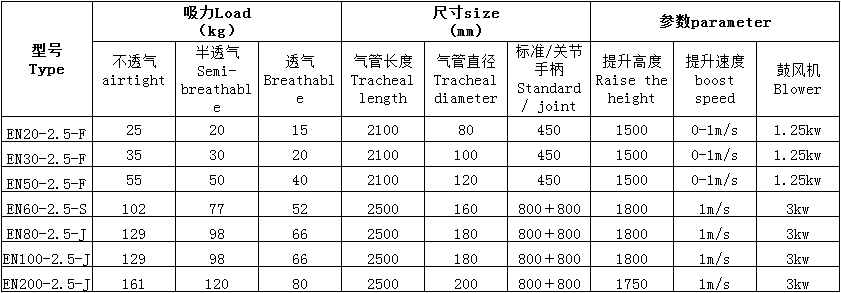

Equipment selection table:

Vacuum pump table

Air tube