Products

Suction cup and vacuum pump

- Commodity name: Suction cup and vacuum pump

- Product Description

-

Introduction to Vacuum Suction Cups

Vacuum suction cups are one of the vacuum device actuators, also known as vacuum lifting tools and vacuum nozzles. The suction cup material is made of nitrile rubber, which has a large breaking force, and is widely used in various vacuum gripping devices, such as in the packaging industry: lifting cartons, woven bags, blister boxes, etc.; in the home appliance industry: handling refrigerators, air conditioners, televisions, etc.; in the sheet metal industry for handling stainless steel plates and other materials; in the building materials industry: lifting wooden boards, tiles, marble, curtain wall glass, etc.; and in the glass industry for gripping and transporting glass products using vacuum suction cups. There are various types of vacuum suction cups; rubber suction cups can operate at high temperatures, while silicone rubber suction cups are very suitable for gripping rough-surfaced products; polyurethane suction cups are very durable. Additionally, in actual production, if oil resistance is required for the suction cup, materials such as polyurethane, nitrile rubber, or vinyl-containing polymers can be considered for manufacturing the suction cup. Generally, to avoid scratching the surface of the products, it is best to choose suction cups made of nitrile rubber or silicone rubber with corrugated tubes.

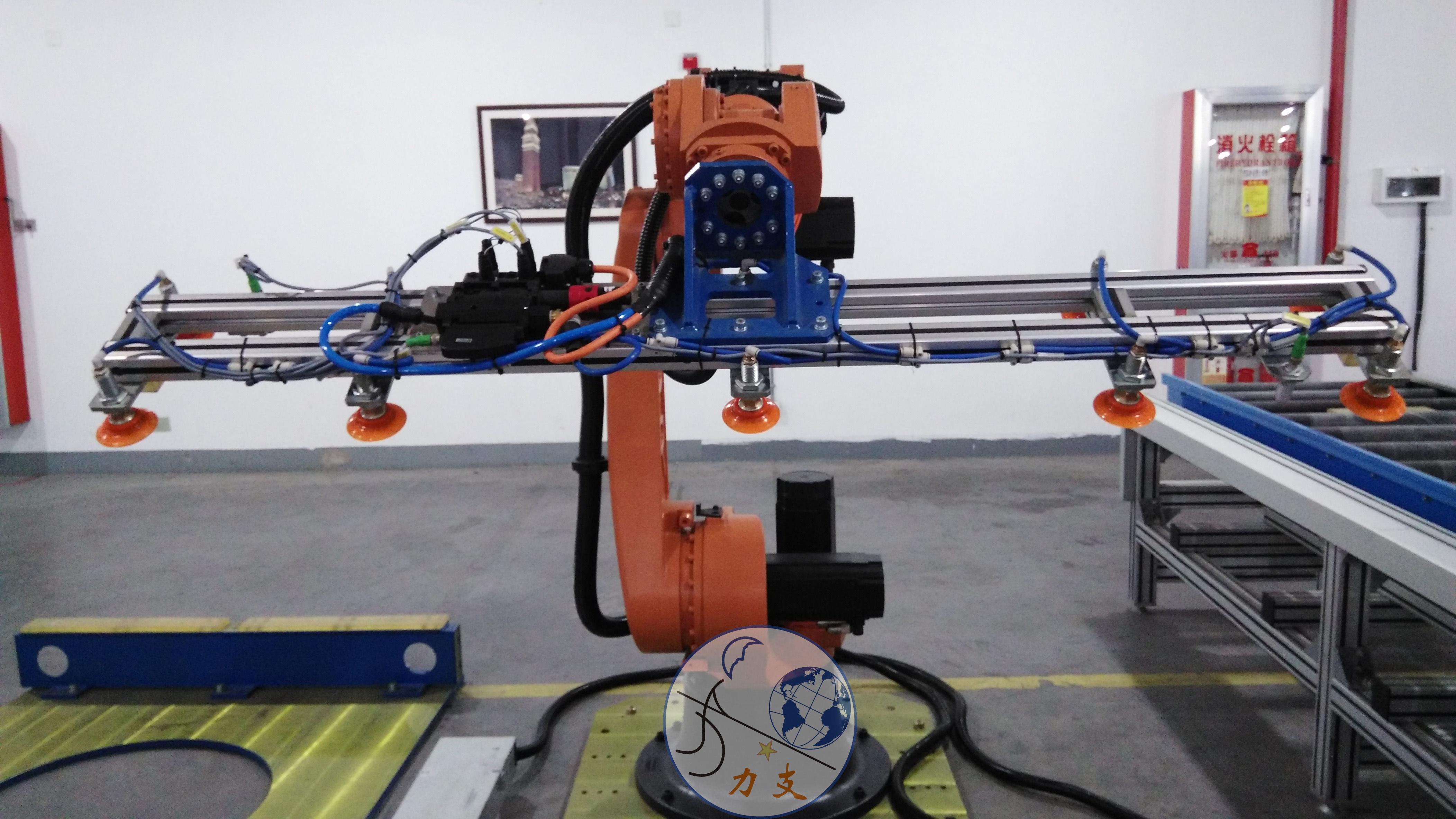

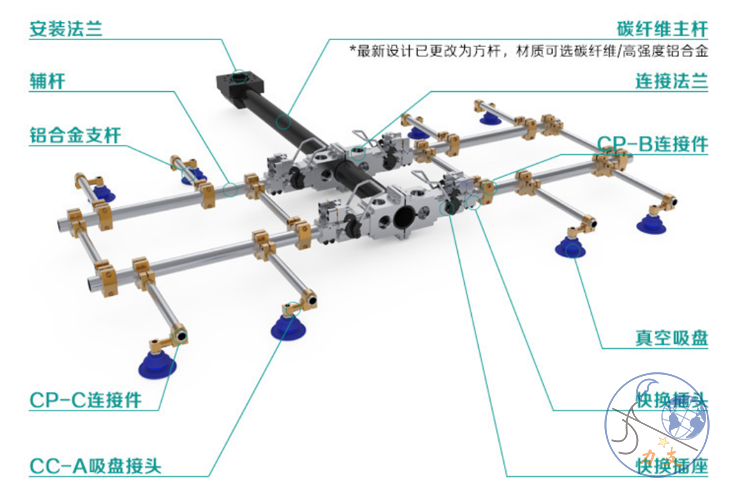

Introduction to End Effectors

Advantages

1, Quick-change flange: adoptsATCquick-change structure, short waiting time, and high versatility.

2, Stable structure: the newly upgraded square main rod has better rigidity, enhancing the ability to assist with line matching.

3, Simple operation: adopts front-end support rod quick-change, making component replacement easy and convenient.

4, High cost-performance ratio: the cost of the main rod is relatively low, and adding an end effector only requires increasing the support rod part, making it more economical and practical.

Highlights

1, Lightweight aluminum alloy material reduces robot energy consumption,

2, Fast vacuum generation, short response time, improving the operating rhythm of the automation line

3, High flexibility, high precision, stable operation, extending the service life of the robotic arm

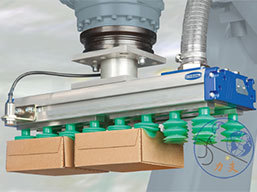

Case Display:

Large-area vacuum suction cup end effector Spider-type end effector Sponge-type suction cup end effector

Combination-type suction cup end effector Embedded vacuum suction cup Spring buffer suction cup

Function description of main vacuum components:1. Vacuum pump: oil-free, air-cooled rotary vane vacuum pump, connected to380V, three-phase power can generate vacuum, which is the core part of the vacuum system, with a maximum vacuum degree of85%;2. Vacuum suction cup: used to adhere to the surface of the workpiece, rubber contacts the workpiece to ensure no damage to the workpiece surface;

3. Pressure sensor: used to visually display the system's vacuum pressure to the operator, providing safety assurance;

4. Vacuum filter: used to filter impurities and particles from the workpiece surface or air, ensuring the service life of the vacuum pump;

5. Vacuum pressure switch: diaphragm type, transmits electrical signals to the alarm system when the vacuum system pressure is insufficient;

6. Manual ball valve: used to manually open or close the passage between the vacuum pump and the suction cup for easy maintenance;

7. Solenoid valve: controls the switching of the passage between the vacuum pump and the suction cup, and between the suction cup and the atmosphere;

8. Alarm indicator light: when the suction force of a single suction cup is insufficient, the corresponding indicator light alarms.

9. Vacuum one-way valve: when a power failure occurs in the system, it automatically shuts off the passage between the vacuum pump and the atmosphere, locking the vacuum energy of the accumulator, providing sufficient holding time to ensure that the workpiece does not

suddenly drop;Germany Becker BECKER Germany Elmo Rietschle Germany Busch Japan ORIONWorking principle of BECKER:

• Single-axis direct drive, this simple and durable design meets the working principle of long-term use, low maintenance costs, and low operating costs. The vanes of the vacuum pump are inserted into the slots of the rotor that is concentric with the pump body. When the rotor rotates, centrifugal force pushes the vanes to rotate within the pump cylinder wall, creating several gas chambers in the compression space between the rotor and the pump cylinder. When the gas chamber passes through the inlet end, air flows in; the centrifugal force of the continuously rotating rotor compresses the inhaled air, and finally, the compressed air is expelled through the outlet end. The pump operates in an absolutely oil-free state; the compression chamber is sealed with rotating blades (made of special environmentally friendly materials, with high sealing performance and long service life). Two combined blowers ensure a low delivery air temperature. The intake filter and regulating valve are designed as integrated components based on compact modern principles. The pump cover ensures that the pump emits minimal noise during operation.

Reliability:

• Made of high-quality materials, according to ISO9001 and CE certification quality management. The computer control engineering of automated processing equipment can ensure the production of standardized and precise products. In vacuum operations, when the vacuum pump stops running, a check valve is installed at the suction port to prevent lubricating oil from flowing back, ensuring safety.

Miniaturization:

• The vacuum pump's rotating shaft and cylinder are directly connected to the flange-shaped motor, resulting in a simple structure. Utilizing the cooling method of the motor's cooling fan, it is compact and lightweight.

Comfortable environment:

舒适的环境:

• Based on air cooling and the recycling of lubricating oil, a lubricating oil cylinder with a special structure to remove lubricating oil mist is installed for clean air discharge, low noise, low vibration, and can be used in any environment.

Easy to manage:

• Simple structure, air cooling method, no need to replace the oil mist separator, maintenance and repair are very simple, and it can be used for a long time. When lubricating oil needs to be replaced, there is no need to replace other consumables.

Suction cup and vacuum pump:Suction cups coupled with vacuum pumps form the backbone of modern material handling systems across manufacturing, automation, and robotics. These systems operate on Bernoulli's principle, where controlled vacuum generation creates differential pressure to securely grip smooth surfaces without mechanical damage. Industrial-grade suction cups typically employ elastomers like polyurethane or nitrile rubber, formulated to maintain flexibility across temperature extremes (-40°C to 120°C) while achieving friction coefficients up to 2.5 on polished metals. The vacuum pump's critical performance parameters include ultimate vacuum level (typically 80-95 kPa below atmospheric), flow rate (measured in liters per minute), and response time - with high-end ejector pumps achieving full vacuum in under 50 milliseconds for high-speed pick-and-place operations.

Suction cup and vacuum pump:Suction cups coupled with vacuum pumps form the backbone of modern material handling systems across manufacturing, automation, and robotics. These systems operate on Bernoulli's principle, where controlled vacuum generation creates differential pressure to securely grip smooth surfaces without mechanical damage. Industrial-grade suction cups typically employ elastomers like polyurethane or nitrile rubber, formulated to maintain flexibility across temperature extremes (-40°C to 120°C) while achieving friction coefficients up to 2.5 on polished metals. The vacuum pump's critical performance parameters include ultimate vacuum level (typically 80-95 kPa below atmospheric), flow rate (measured in liters per minute), and response time - with high-end ejector pumps achieving full vacuum in under 50 milliseconds for high-speed pick-and-place operations.

Key words: