oil drum

Application fields and characteristics:

The EN-2.5-J vacuum tube lifting device uses the principle of vacuum to lift and move workpieces, especially suitable for frequently lifting and moving oil drums, bagged packaging, cartons, and sheets, with a handling weight of up to 300Kg. When lifting workpieces, there is no need for cranes, robotic arms, hydraulic cylinders, or other power sources; the operator only needs to use the control handle to adjust the system's vacuum level to easily lift and transport the workpieces. The higher the vacuum level, the higher the workpiece is lifted; when the vacuum level decreases, the workpiece is gently lowered.

Application range:

Loading and unloading machine parts or electronic components

|

|

| Lifting unit Multiple lifting units can be selected, and the lifting height and workpiece weight depend on the maximum load of the lifting device. The lifting tube is designed to be compact and easy to operate. Two basic lifting strokes: 1700mm 2100mm Stainless steel material available as an option |

Precise one-handed operation, 90° joint ergonomic design, convenient for both left and right hands. Integrated quick-change head, allowing different suction cups to be changed in seconds. |

Extracting and loading cargo boxes or products into boxes.

Handling woven bags, snake skin bags, rubber blocks.

Stacking shrink film packaging or bagged packaging.

Functional design:

One-handed operation can lift 35Kg items.

Ergonomic operation, making it easy to handle heavy items.

A complete power supply device (electricity, compressed air, vacuum) integrated with the suspension rail.

Limit block safely adjusts the sliding area.

Load detection valve for selection, safe and reliable.

Technical specifications:

Maximum size: approximately 8×30m

Maximum load: approximately 700Kg (depends on the weight of the beam)

Minimum track weight: only 2.7kg/m

Suitable for single-arm, double-arm, and single-rail systems.

|

|

|

|

|

|

|

|

|

Special design |

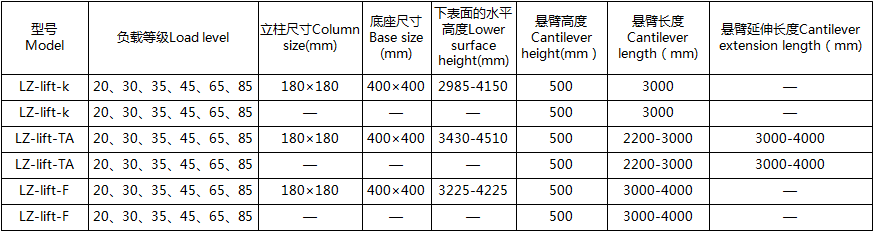

K: Hinged suspension; TA: Telescopic cantilever; F: Flat top cantilever.

Equipment selection table

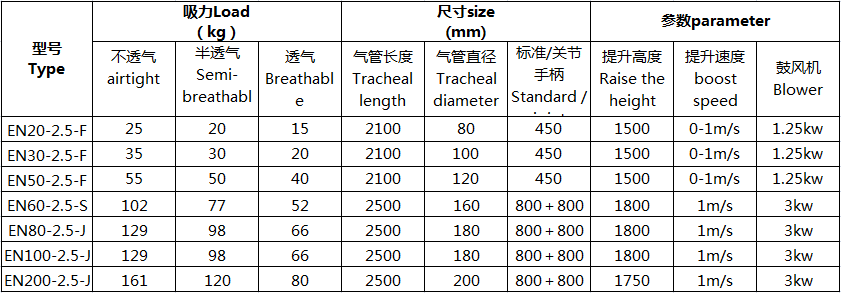

Air tube

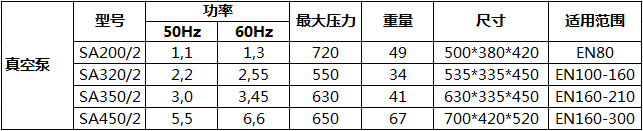

Vacuum pump