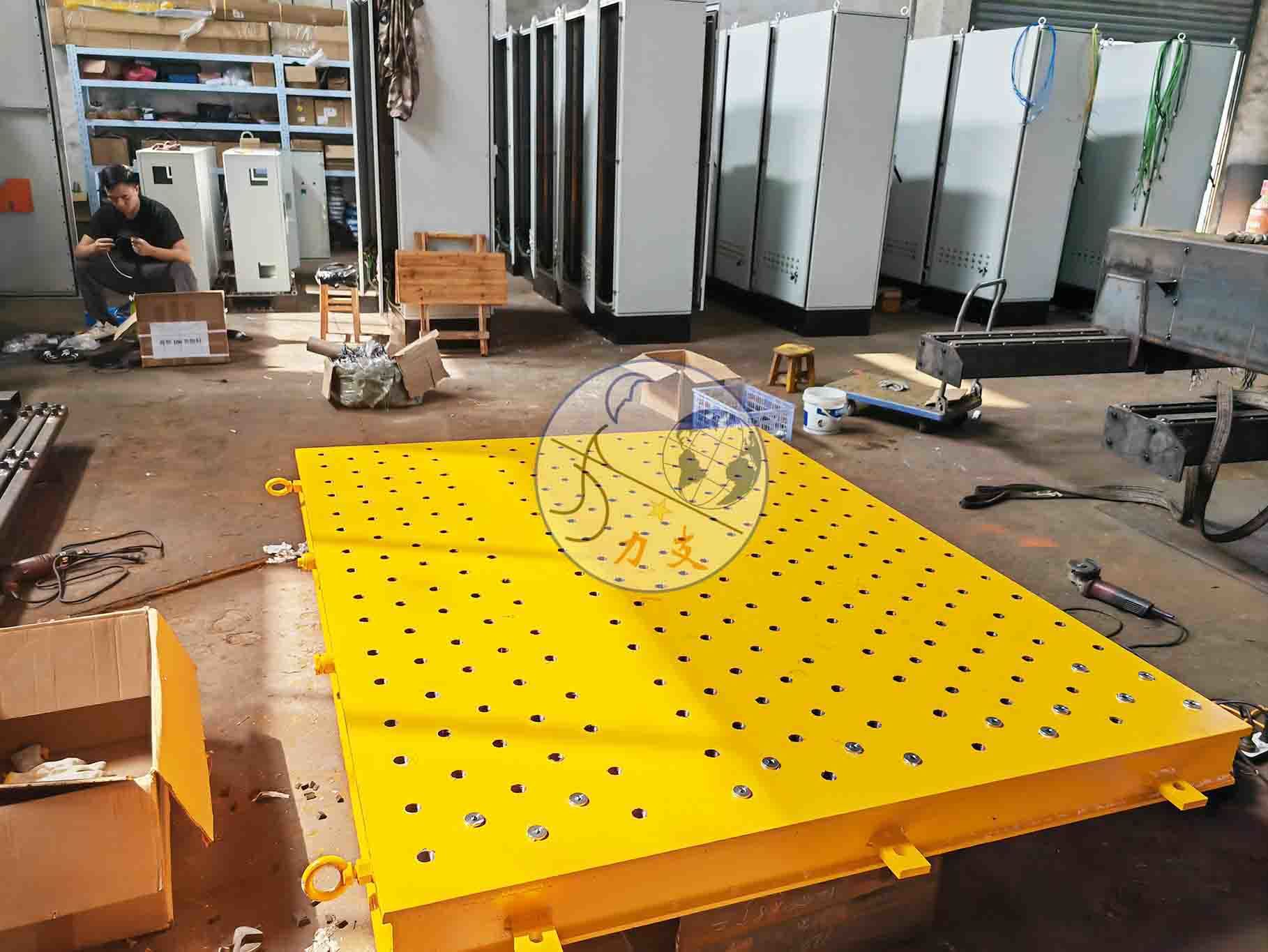

Matrix suction cup

Non-standard design and matrix suction cups:

Wuxi LZ can provide customers with matrix multi-point suction cups that meet processing requirements in various fields of different processing industries. Its characteristics include high processing accuracy and faster adsorption clamping compared to traditional positioning clamping methods. Especially for applications in large gantry milling machines, planers, vertical lathes, and CNC machine tools, a one-stop service is provided. The aim is to liberate frontline workers engaged in dangerous, heavy, tedious, and labor-intensive work environments, reduce labor intensity, and improve work efficiency and yield..

Basic module

The basic module is the core component of the vacuum lifting machine, which includesvacuum generation device, motion control device, detection and alarm device, and main frame. Its composition can be divided into3categories to meet customer needs. As follows:

|

|

|

||

|

Sheet cutting

Vacuum suction cup material Q345, tempered, precision ground

Sheet cutting range L2M*W1.6M,

cutting sheets at equal distances within a limited range.

|

Sheet edge milling

Vacuum suction cup material polyester fiber,

vacuum generated around any edge within the suction cup surface,

for milling the edges of the sheet.

Sheet processing

Vacuum suction cup material aviation aluminum plate

|

Equidistant processing within the suction cup surface, unabsorbed

areas can automatically close the vacuum

and can be precisely controlled.

Processing method

LZ 4200 vertical lathe precision machining

LZ rubber suction cup

|

|

|

|

||

|

Each set of suction cups has a pulling force of 1T, with a bottom platform support

Multi-hole suction cup

|

Integrated vacuum chamber, independent adsorption at any point

Multi-functional lifting

|

多孔吸盘

集成式真空腔体,任意点位可独立吸附

|