Products

Diamond Palm Suction Hoist

- Commodity name: Diamond Palm Suction Hoist

- Product Description

-

King Kong PalmVacuum LifterIntroduction

Application

Suitable for flat, high airtightness panel products, such as:

ØLaser cutting machine loading and unloading ØHollow glass loading and unloadingØFireproof board cutting loading and unloadingØSandwich panel packaging loading and unloading

ØHollow glass loading and unloadingØFireproof board cutting loading and unloadingØSandwich panel packaging loading and unloadingAdvantages

ØEfficient, non-destructive handling of large heavy panelsØProtects operator safety and reduces labor intensityØCompact product, easy to use, creating value for customersHighlights

1, operating handleLtype design, horizontal pushing is more labor-saving

2, both the crossbeam and main beam are adjustable, covering a wider range of product specifications

3, vacuum pump has a start-stop function, reducing equipment energy consumption

4, the electric control is equipped with phase loss protection, increasing safety factor

5, handle can be optionally equipped with wireless remote control, beautiful, avoiding wire wear

6, negative pressure alarm function, preventing falling objects from injuring people

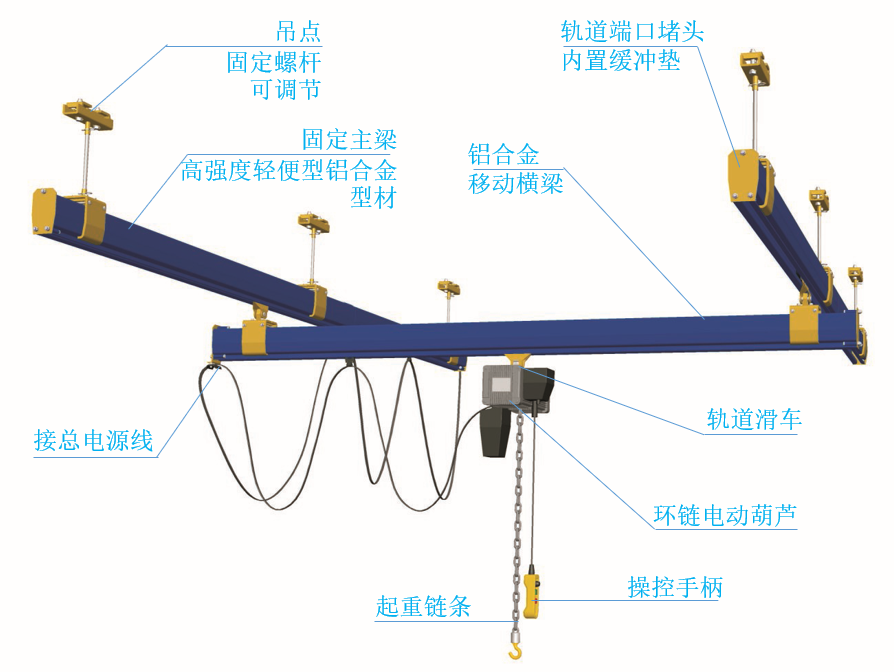

Components and Functions

Case Display

Model: 5T/12m Wired Model: 5T/12m Rechargeable Wireless

Model: 10T/10m Wired Model: 5T/9m Rechargeable Wireless

Model: 5T/14m Wired Model: 5T/12m Wired

Model: 5T/12m Rechargeable Wireless Version Model: 3T/12m Wired

Model: 20T/16m Intelligent Vacuum Lifter Model: 25T/16m Outdoor Vacuum Lifter Basic Module

The basic module is the core component of the vacuum lifter, which includesVacuum generation device, motion control device, detection alarm device, and main frame. Its composition can be divided3into major categories to meet customer needs. As follows:

Horizontal HandlingStandard type, sturdy metal shell, built-in vacuum generation system,negative pressure alarm system, motor protector.•Load 500kg90° RotationNewly added cylinder rotation mechanism based on the standard type,the rotation process is fast and stable•Load 200kg180° RotationNewly added motor and rotation mechanism based on the standard type, the rotation process is smooth, with sufficient rotation power•Maximum load 500kg

Horizontal HandlingStandard type, sturdy metal shell, built-in vacuum generation system,negative pressure alarm system, motor protector.•Load 500kg90° RotationNewly added cylinder rotation mechanism based on the standard type,the rotation process is fast and stable•Load 200kg180° RotationNewly added motor and rotation mechanism based on the standard type, the rotation process is smooth, with sufficient rotation power•Maximum load 500kg

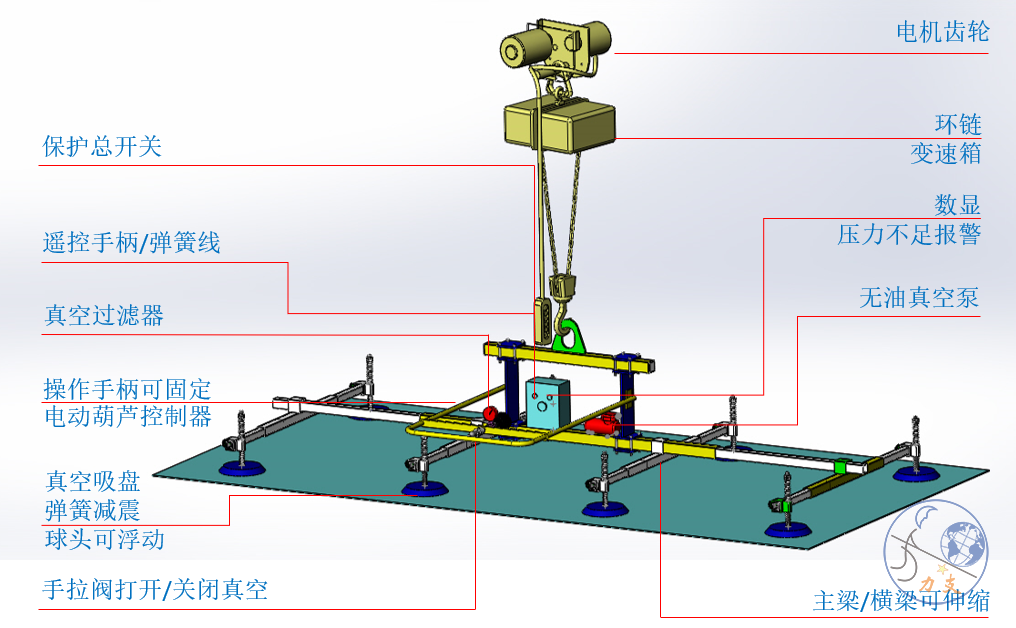

Control BoxIntegrated components of the vacuum system, including main power switch, alarm, pressure switch, etc. Used to control the entire end picker.Japan ORION Vacuum PumpOil-free vacuum pump, power generation device, maintenance-freeVacuum Suction CupContacts the product surface, forming negative pressure, adsorbing the workpiece. Can be equipped with rectangulartube sliding blocks, spring buffer support rods.

Control BoxIntegrated components of the vacuum system, including main power switch, alarm, pressure switch, etc. Used to control the entire end picker.Japan ORION Vacuum PumpOil-free vacuum pump, power generation device, maintenance-freeVacuum Suction CupContacts the product surface, forming negative pressure, adsorbing the workpiece. Can be equipped with rectangulartube sliding blocks, spring buffer support rods.

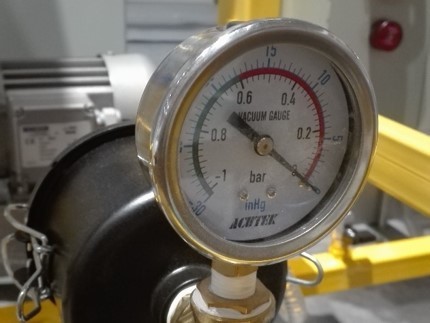

Diverter PipeCollects the negative pressure from each suction cup to the air storage tank. Each joint is equipped with a ball valve switch.Hand Slide ValveThe hand slide valve is a two-position three-way switch valve, controlling the suctionand release of the workpiecePressure GaugeOperators can visually check the negative pressure value, assess the vacuum level, and manually adjust the hand slide valve based on the pressure value.Aluminum Alloy Cantilever Crane

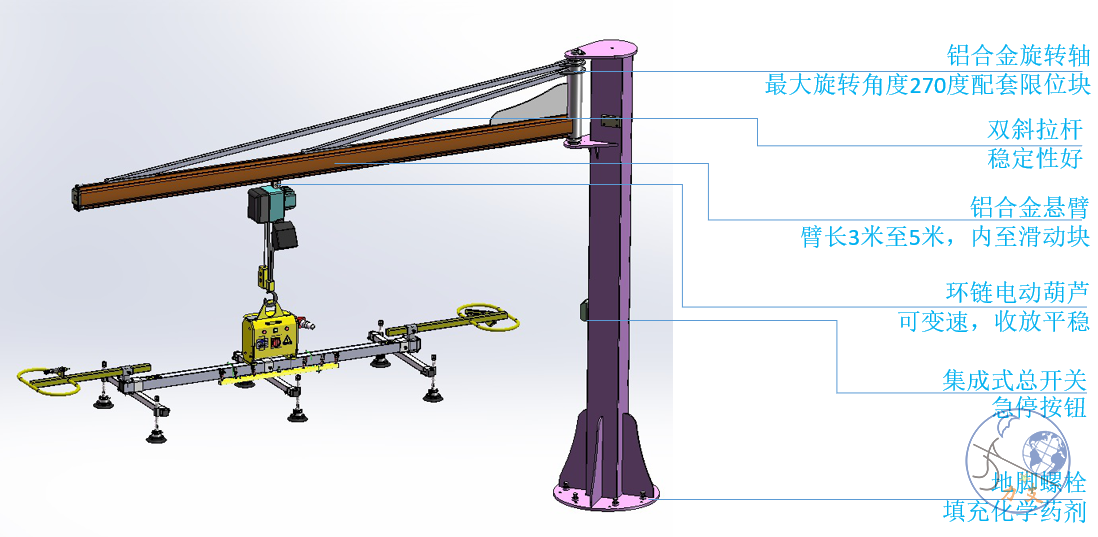

Diverter PipeCollects the negative pressure from each suction cup to the air storage tank. Each joint is equipped with a ball valve switch.Hand Slide ValveThe hand slide valve is a two-position three-way switch valve, controlling the suctionand release of the workpiecePressure GaugeOperators can visually check the negative pressure value, assess the vacuum level, and manually adjust the hand slide valve based on the pressure value.Aluminum Alloy Cantilever CraneFixed column type: directly fixed to the ground or driven into the ground, using chemical expansion bolts for reinforcement.

ØHugging column type: directly fixed to the steel concrete column, using chemical expansion/Hanging type: directly fixed to the steel structure, using full welding.ØCrossbeam Installation Method/Hanging type: directly fixed to the steel structure, using full welding. ØTension type: easy to install, better rail extensibility, high cost performance./Hanging type: directly fixed to the steel structure, using full welding.

ØTension type: easy to install, better rail extensibility, high cost performance./Hanging type: directly fixed to the steel structure, using full welding.Down-support type: saves space, increases lifting height.

ØImported aluminum alloy rail system, high hardness, corrosion-resistant.Ø下撑式:节省空间,增加提升高度。Highlights

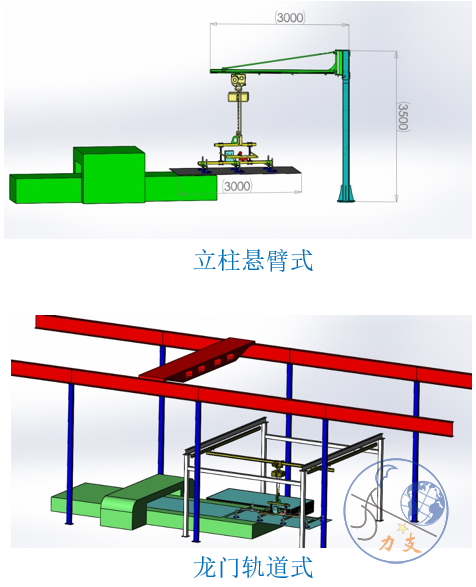

Ø进口铝合金制轨道系统,硬度高,耐腐蚀ØThe sliding block is built into the track, with low resistance and easy movement.ØCarbon steel columns, sturdy and durable, with surface oxidation treatment, corrosion-resistant.ØColumn-mounted motor protection switch to protect electrical appliances.ØThe column has a built-in rotating head and an external fixed bracket.270°RotationØThe force column can be equipped with a rotating motor for automatic rotation, suitable for heavy workpieces.Track installation method

ØSuspension type: directly connected to the steel structure above the ceiling./Fixed to the cement surface using welding or expansion bolts.ØGantry type: equipped with a gantry frame, fixed with clamping plates and bolts.

Highlights

ØOutstanding low friction, low resistance, and easy movement.ØSuitable for pneumatic suction cranes and diamond palm suction cranes.ØSuitable for pneumatic hoists and electric hoists.ØCan operate on dual tracks, and can be extended locally.

YALEElectric chain hoist, clean hoist

Product load:250kg-2500kg

Lifting speed:0.2m/s,Optional

Lifting height: standard3000mm,Optional

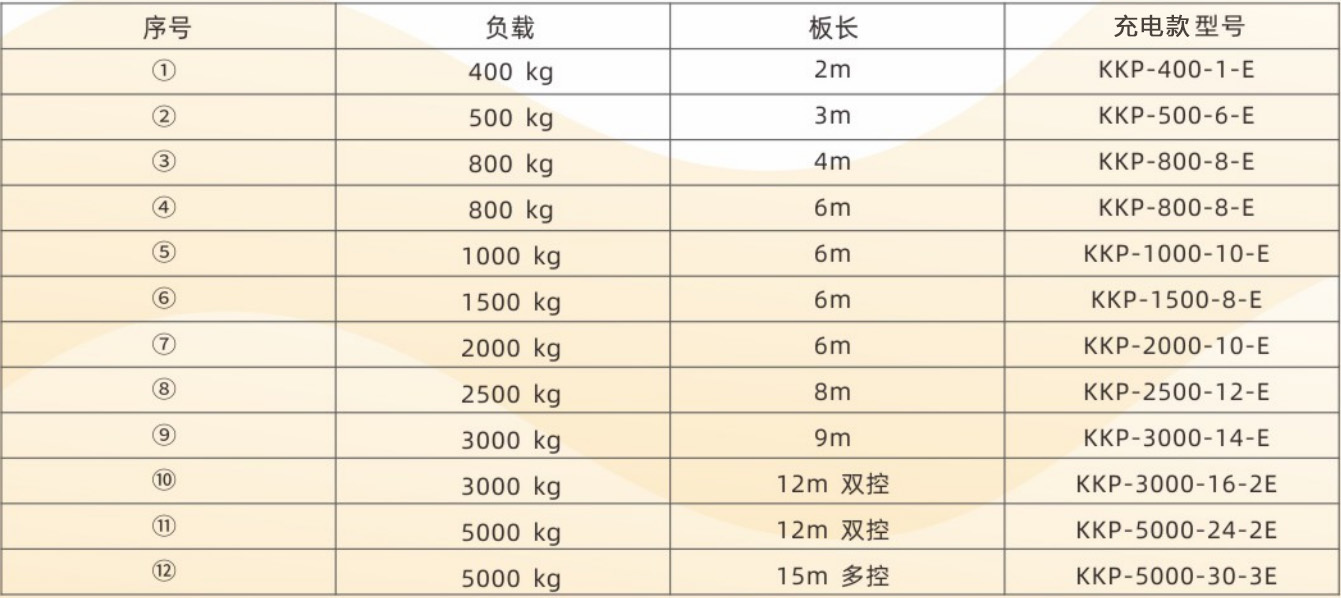

ØThe gear device uses oil-immersed lubrication for smoother gear transmission.ØStandard configuration with main circuit contactor to enhance work safety.ØStandard equipped with thermal overload protection device.ØOptimized shell structure for better heat dissipation, beneficial for cooling.ØPower failure protection function, sudden power loss will not cause heavy objects to fall freely.ØThe control handle is designed for greater safety for the human body.42Low voltage control,IP65Protection levelØThe spring wire is coated with wear-resistant polyurethane fiber.Equipment specifications:

Diamond Palm Suction Hoist:A groundbreaking suction hoist is transforming the way industries handle heavy and delicate materials. Designed for precision and efficiency, this cutting-edge device combines robust engineering with advanced vacuum technology to lift and transport loads up to several tons with ease. Its versatility makes it indispensable in sectors like construction, manufacturing, logistics, and glass processing, where safety and accuracy are paramount.

The hoist’s standout feature is its diamond-patterned palm, which ensures maximum grip on smooth or uneven surfaces without causing damage. Capable of adhering to materials like glass, metal, and stone, it operates seamlessly in challenging environments, from high-temperature workshops to outdoor construction sites. With a lifting capacity ranging from 500 kg to 5,000 kg, the equipment caters to diverse operational needs while maintaining exceptional stability.

What sets this system apart is its intelligent pressure control, which automatically adjusts suction force to prevent slippage or material deformation. The ergonomic design includes wireless remote operation, allowing operators to manage lifts from a safe distance. Additionally, its energy-efficient pump reduces power consumption by 30% compared to conventional models, lowering operational costs.

Key words: