Products

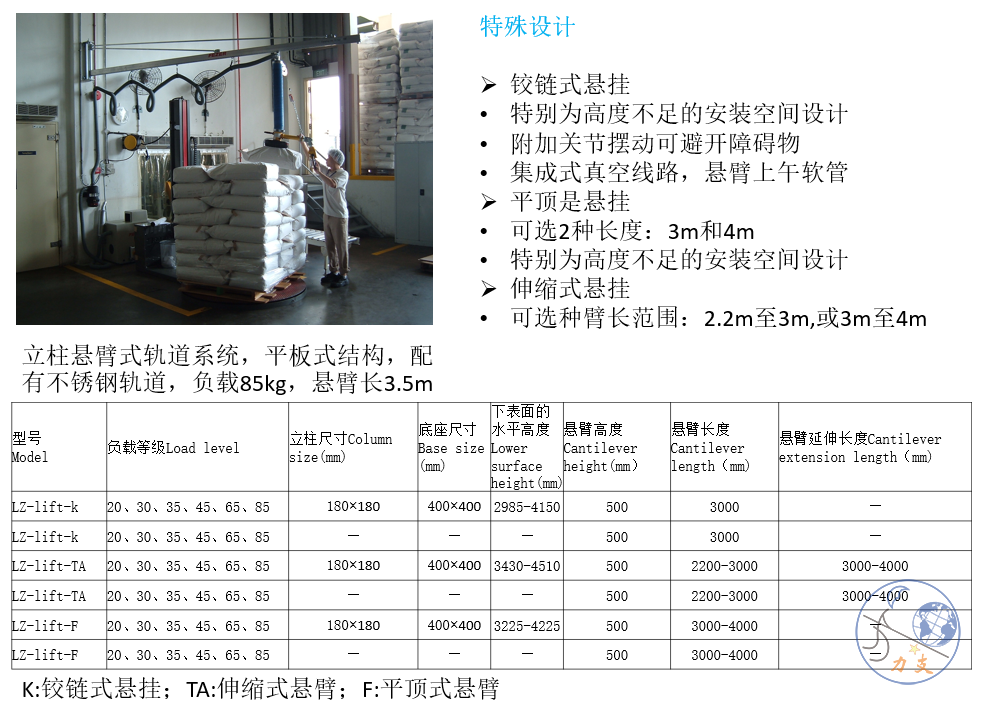

Elephant trunk suction crane

- Commodity name: Elephant trunk suction crane

- Product Description

-

Elephant trunkIntroduction to pipe lifting devices

Application

ØLoading and unloading machine parts or electronic componentsØExtracting loading boxes or products into boxesØHandling woven bags, snake skin bags, rubber blocksØStacking shrink film packaging or bag packaging

ØLoading and unloading machine parts or electronic componentsØExtracting loading boxes or products into boxesØHandling woven bags, snake skin bags, rubber blocksØStacking shrink film packaging or bag packagingFunction

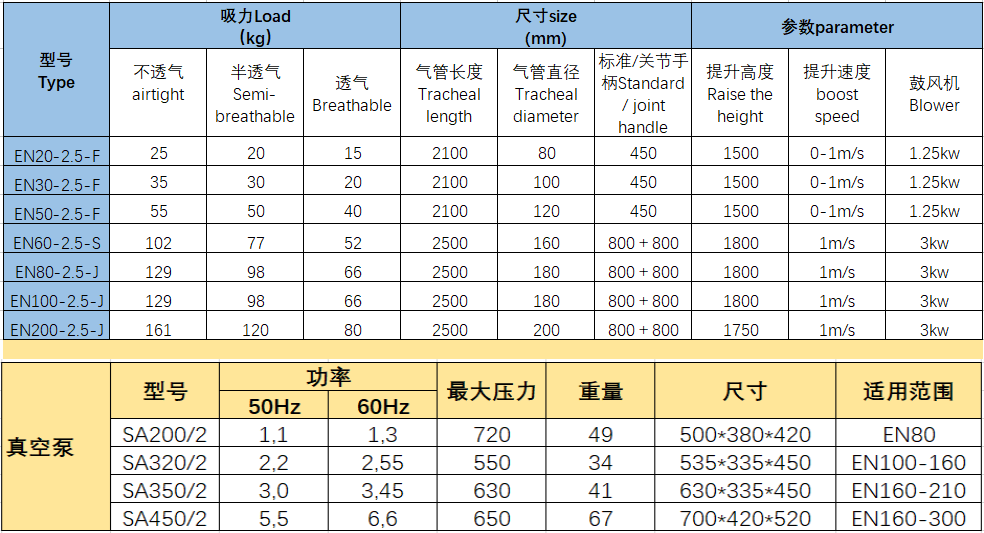

ØCan lift 35Kg heavy objects with one handØErgonomic operation, easy to handle heavy objectsØComplete power supply device (electricity, compressed air, vacuum)ØIntegrated with cable and suspension railØLimit block safely adjusts the sliding areaØSelection load detection valve, safe and reliableSpecifications:

ØMaximum size: approximately 8×30m (track range)ØMaximum load: approximately 700Kg (depends on the weight of the beam)ØMinimum track weight: only 2.7kg/mØSuitable for single-arm, double-arm, and single-rail systemsBasic module

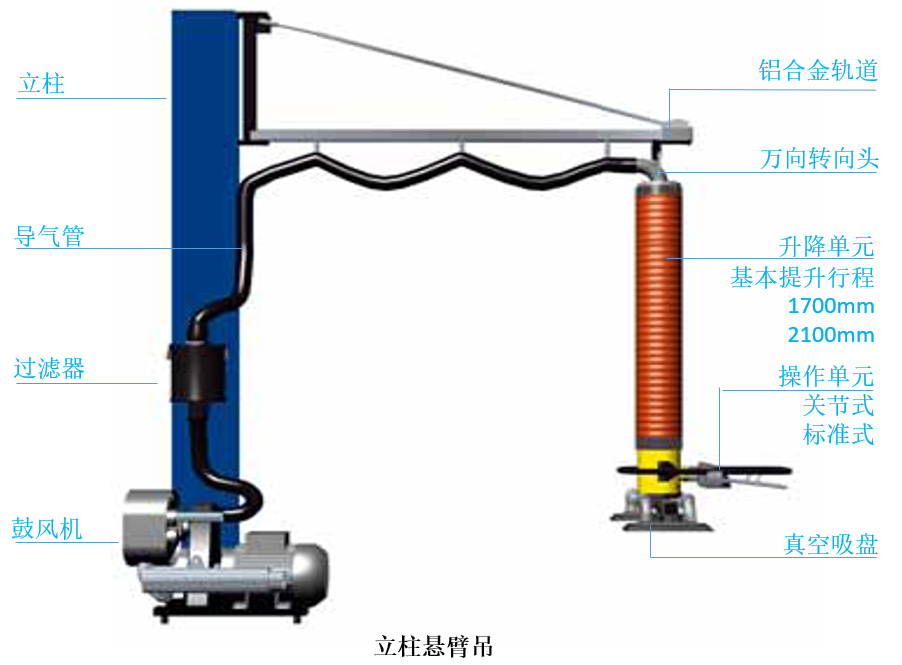

The basic module is the core component of the vacuum suction lifter, which includes the vacuum generation device, motion control device, and main frame.

1.Vacuum blower:Belt-driven, oil-free air-cooled rotary vane vacuum pump, characterized by high speed and large flow. Can

380V, composed of a motor and a fan. Three-phase power can generate vacuum, which is the core part of the vacuum system, with the highest vacuum

degree85%, with an air extraction volume of 225 cubic meters per hour. Spare parts or consumables:a, drive belt;b, belt tensioner

2. Lifting air tube:Contracts or extends with the increase or decrease of internal vacuum pressure to achieve vertical displacement;

3. Rotary joint:The bearing design allows the lifting air tube to rotate 360degrees from the top, with a built-in one-way valve that can automatically lock the vacuum when the vacuumpump loses power, extending the pressure-holding time and ensuring system safety;

4. Control handle:

The suctionrelease/lifting/and lowering of the workpiece are all completed through this control handle;/5. Extension flange:

Connects the suction cup to the control head, extending the distance;6. Vacuum filter:

Used to filter impurities and particles on the workpiece surface or in the air, ensuring the service life of the vacuum pump;7. Vacuum guide pipe:

Used for connecting the vacuum blower to the vacuum suction cup, high pressure and corrosion-resistant;8. Safety relief valve:

Automatically opens to relieve pressure when the system vacuum pressure reaches the set value, to protect the vacuum pump;9.

Quick-change connector:Used for quickly changing different suction cups, only takes3seconds to change a suction cup.Combination form

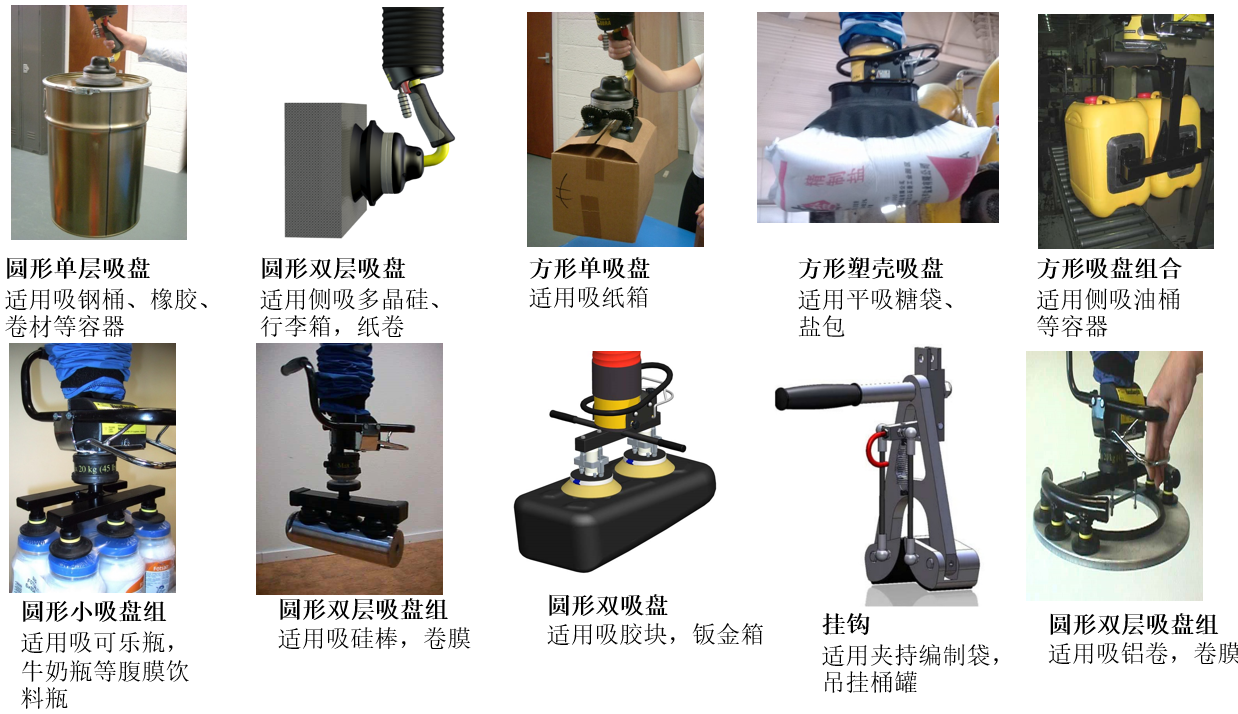

Different combination forms complete different suction and lifting. Its composition can be divided into ten categories, with diverse combinations to meet various needs.

As follows:

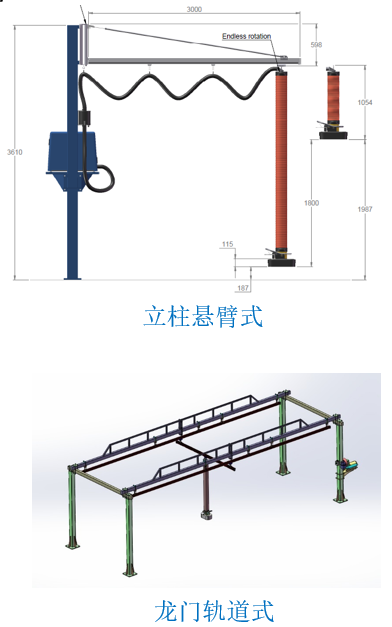

Aluminum alloy cantilever crane

Column installation method

Fixed column type: directly fixed to the ground or driven into the ground, using chemical expansion bolts for reinforcement.

ØClamping column type: directly fixed to the steel concrete column, using chemical expansion bolts./Hanging type: directly fixed to the steel structure, using full welding. ØBeam installation method/Hanging type: directly fixed to the steel structure, using full welding.ØTension type: easy to install, better rail extensibility, high cost performance./Hanging type: directly fixed to the steel structure, using full welding.

ØBeam installation method/Hanging type: directly fixed to the steel structure, using full welding.ØTension type: easy to install, better rail extensibility, high cost performance./Hanging type: directly fixed to the steel structure, using full welding.Support type: saves space, increases lifting height.

ØHighlightsØImported aluminum alloy rail system, high hardness, corrosion-resistantRails with built-in sliding blocks, low moving resistance, easy to move

ØCarbon steel columns, sturdy and durable, surface oxidation treatment, corrosion-resistantØColumn installation motor protection switch, protects electrical appliancesØColumn with built-in rotating head, external fixed bracket, canØrotate 270°Ø立柱内置旋转头,外置固定支架,可270°旋转ØThe force column can be equipped with a rotating motor, allowing for automatic rotation, suitable for heavy workpieces.Column-type gantry crane

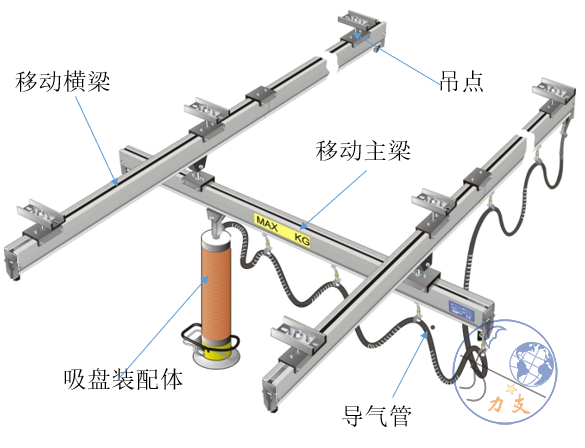

Column installation method:

Gantry type: Four or single columns fixed to the ground, each equipped with fixed cross beams and fixed vertical main beams, with a multi-track rail system installed on the fixed beams.

Rail installation method

ØSuspension point type1: Directly connected to the fixed beam on the gantry frame, using bolts or clamp plates for fixation.ØSuspension point type2: Directly fixed to the steel structure above the ceiling/Fixed to the cement surface, using welding or expansion bolts.

Rails with built-in sliding blocks, low moving resistance, easy to move

ØOutstanding low friction, low moving resistance, lightweight operation.ØApplicable to pneumatic suction cranes, diamond palm suction cranes.ØApplicable to pneumatic hoists, electric hoists.ØCan operate on dual tracks, and can be extended locally.ØHigh stability, high load capacity, high safety factor.ØLarge span, wide working range.

Equipment specifications:

Key words: