Safety Precautions

1. Operational Safety

1Suction Cup Attachment: Move the vacuum lifting machine above the board, then lower it onto the board, ensuring the suction cup adheres to the workpiece;

2Suctioning the Board: Push the pull valve forward, and the vacuum suction cup will automatically attach to the board. When the vacuum reaches the required level, indicated by the green light, the lifting machine can be moved;

3Releasing the Board: Press the safety pin on the pull valve, pull the pull valve backward, and the board will be released;

4Separate Control of Suction Cups: When the length of the board is less than the distance between the outermost suction cups, each suction cup can be closed using the manual ball valve on it. The suction cups that are not closed will adhere to the board, preventing vacuum leakage;25

Do not let the suction cup directly contact the ground!6

Do not exceed the lifting capacity of the lifting machine!7

Do not use equipment when alarms are sounding!2. Workshop Safety

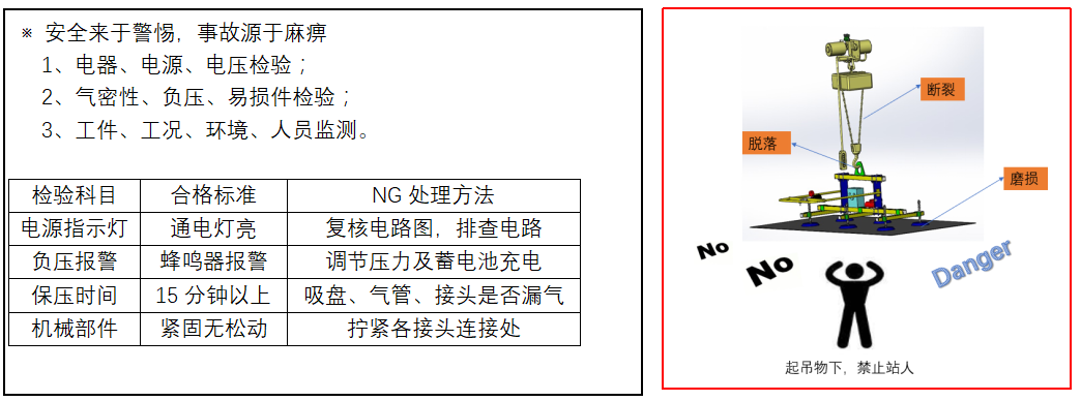

Do not work in unsafe positions under lifted objects: Avoid staying under lifted items, refueling or operating machines, repairing, adjusting, welding, cleaning, etc., while distracted.

1Not wearing protective gear: Safety helmets, safety shoes, protective gloves; do not neglect their importance when protective gear is required.

2Unsafe clothing: Do not wear loose clothing near rotating machinery, and female employees should tie up long hair when operating rolling machines.

3Ignoring safety warnings and operating incorrectly: Starting, stopping, or moving machines without permission. Not signaling when starting or stopping, and not securing switches can lead to unintended movements or electrical leaks.

4Causing safety devices to fail: Safety devices that are removed or blocked, or incorrectly adjusted, can lead to failure.

Do not let the suction cup directly contact the ground!Using unsafe equipment: Temporarily using unstable facilities or equipment without safety devices.

Do not exceed the lifting capacity of the lifting machine!Using hands instead of tools: Using hands instead of manual tools, clearing chips with hands, not using fixtures to secure workpieces, and improperly storing items.

Do not use equipment when alarms are sounding!8

Taking risks by entering dangerous areas: Approaching leaking materials, hazardous chemical rooms, or construction sites.The 'Four Checks' of Safety Inspection

Check the site and identify hazards;

1、Check mindset;

2、Check management and systems;

3、Check accident handling.

4、Check the handling of the accident.