Diamond Palm Suction Hoist

Date:

2025-07-02

Diamond Palm Suction Hoist:Industries dealing with fragile or high-value items, such as automotive assembly lines or aerospace component manufacturers, benefit greatly from its non-marking pads and vibration-free movement. The hoist’s rapid attachment and release mechanism further enhance productivity, slashing downtime by 50% in repetitive tasks.

King Kong PalmVacuum LifterIntroduction

Application

Suitable for flat, high airtightness panel products, such as:

Advantages

Highlights

1, operating handleLtype design, horizontal pushing is more labor-saving

2, both the crossbeam and main beam are adjustable, covering a wider range of product specifications

3, vacuum pump has a start-stop function, reducing equipment energy consumption

4, the electric control is equipped with phase loss protection, increasing safety factor

5, handle can be optionally equipped with wireless remote control, beautiful, avoiding wire wear

6, negative pressure alarm function, preventing falling objects from injuring people

Components and Functions

Case Display

|  |

| Model: 5T/12m Wired | Model: 5T/12m Rechargeable Wireless |

|  |

| Model: 10T/10m Wired | Model: 5T/9m Rechargeable Wireless |

| |

| Model: 5T/14m Wired | Model: 5T/12m Wired |

|  |

| Model: 5T/12m Rechargeable Wireless Version | Model: 3T/12m Wired |

|  |

| Model: 20T/16m Intelligent Vacuum Lifter | Model: 25T/16m Outdoor Vacuum Lifter |

Basic Module

The basic module is the core component of the vacuum lifter, which includesVacuum generation device, motion control device, detection alarm device, and main frame. Its composition can be divided3into major categories to meet customer needs. As follows:

|

|

| ||

Horizontal Handling Standard type, sturdy metal shell, built-in vacuum generation system, negative pressure alarm system, motor protector. •Load 500kg | 90° Rotation Newly added cylinder rotation mechanism based on the standard type, the rotation process is fast and stable •Load 200kg | 180° Rotation Newly added motor and rotation mechanism based on the standard type, the rotation process is smooth, with sufficient rotation power •Maximum load 500kg | ||

|  | |||

Control Box Integrated components of the vacuum system, including main power switch, alarm, pressure switch, etc. Used to control the entire end picker. | Japan ORION Vacuum Pump Oil-free vacuum pump, power generation device, maintenance-free | Vacuum Suction Cup Contacts the product surface, forming negative pressure, adsorbing the workpiece. Can be equipped with rectangular tube sliding blocks, spring buffer support rods. | ||

|  |  | ||

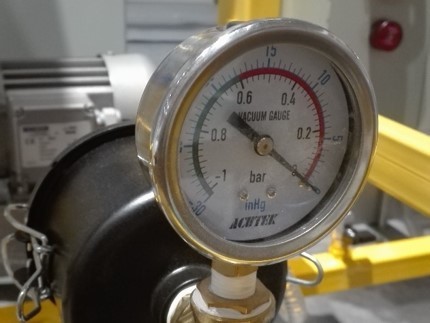

Diverter Pipe Collects the negative pressure from each suction cup to the air storage tank. Each joint is equipped with a ball valve switch.Hand Slide Valve | The hand slide valve is a two-position three-way switch valve, controlling the suction and release of the workpiece | Pressure Gauge Operators can visually check the negative pressure value, assess the vacuum level, and manually adjust the hand slide valve based on the pressure value. Aluminum Alloy Cantilever Crane |

Fixed column type: directly fixed to the ground or driven into the ground, using chemical expansion bolts for reinforcement.

Down-support type: saves space, increases lifting height.

Highlights

Track installation method

Highlights

YALEElectric chain hoist, clean hoist

Product load:250kg-2500kg

Lifting speed:0.2m/s,Optional

Lifting height: standard3000mm,Optional

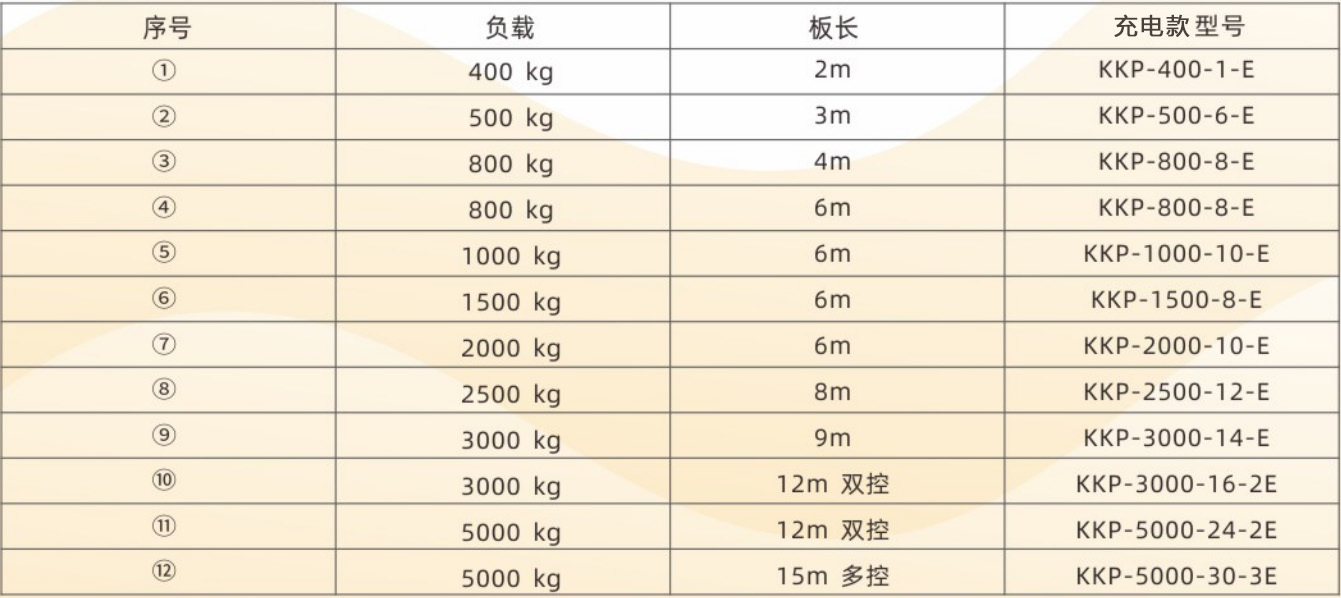

Equipment specifications:

Diamond Palm Suction Hoist:Industries dealing with fragile or high-value items, such as automotive assembly lines or aerospace component manufacturers, benefit greatly from its non-marking pads and vibration-free movement. The hoist’s rapid attachment and release mechanism further enhance productivity, slashing downtime by 50% in repetitive tasks.

As workplace safety regulations tighten globally, this hoist meets stringent international standards, including ISO and OSHA certifications. Its corrosion-resistant materials ensure longevity even in harsh conditions, making it a cost-effective long-term investment.

By merging power, precision, and innovation, this suction hoist is redefining material handling, offering businesses a competitive edge through enhanced efficiency and reliability. Its adaptability across multiple sectors positions it as a game-changer in industrial automation.

Keywords:

Related News

2025-07-02