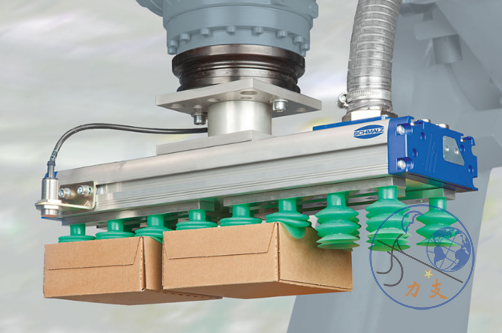

Introduction to Vacuum Suction Cups

Vacuum suction cups are one of the vacuum device actuators, also known as vacuum lifting tools and vacuum nozzles. The suction cup material is made of nitrile rubber, which has a large breaking force, and is widely used in various vacuum holding devices, such as in the packaging industry: lifting cartons, woven bags, blister boxes, etc.; in the home appliance industry: handling refrigerators, air conditioners, televisions, etc.; in the sheet metal industry: handling stainless steel plates and other sheet materials; in the building materials industry: lifting wooden boards, tiles, marble, curtain wall glass, etc.; in the glass industry, achieving the holding and transportation of glass using vacuum suction cups to grab products. There are various types of vacuum suction cups; rubber suction cups can operate at high temperatures, while silicone rubber suction cups are very suitable for gripping rough-surfaced products; polyurethane suction cups are very durable. Additionally, in actual production, if oil resistance is required for the suction cups, materials such as polyurethane, nitrile rubber, or vinyl-containing polymers can be considered for manufacturing the suction cups. Generally, to avoid scratching the surface of the products, it is best to choose suction cups made of nitrile rubber or silicone rubber with corrugated tubes.

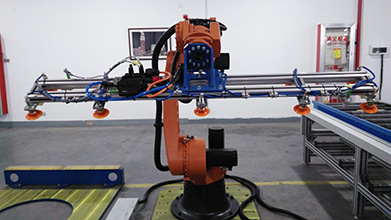

Introduction to End Effectors

Advantages

1, Quick-change flange: adoptsATCquick-change structure, short waiting time, and high versatility.

2, Stable structure: the newly upgraded square main rod has better rigidity, enhancing the ability to assist with line matching.

3, Simple operation: adopts front-end support rod quick-change, making component replacement easy and operation more convenient.

4, High cost-performance ratio: the cost of the main rod is relatively low, and adding an end effector only requires increasing the support rod part, making it more economical and practical.

Highlights

1, Lightweight aluminum alloy material reduces robot energy consumption,

2, Fast vacuum generation, short response time, improving the operating rhythm of the automation line.

3, High flexibility, high precision, stable operation, and increased lifespan of the robotic arm.

Case Display:

|  |  | ||

Large Area Vacuum Suction Cup End Effector | Spider Hand Type End Effector | Sponge Type Suction Cup End Effector |

|  |  | ||

Combination Type Suction Cup End Effector | Embedded Vacuum Suction Cup | Spring Buffer Suction Cup |